Typical parts and applications

From simple brackets and clips to batches consisting of hundreds of parts—examples of the work we take on.

Brackets, clips & mounts

Small partsSmall functional parts for holding sensors, cables or panels in place – ideal candidates for 3D printing where tooling would be expensive for low quantities.

Custom housings & enclosures

ElectronicsApplication-specific housings designed around your PCB and connectors, including mounting points, cable routing and branding where needed.

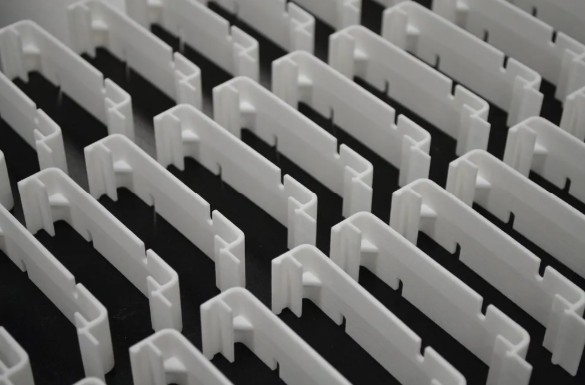

Short-run batches of parts

ProductionSets of identical components produced in batches – ideal for in-house products, kits, or hardware you supply to your own clients.